1. Introduction

This series machine is a kind of advanced

and high efficient milling equipment to prepare the groove of plate before

welding instead of planing. Compared with planer, it has the advantages of

saving power, low investment and high accuracy of surface finish. It is widely

used in the industries as pressure vessel, boiler, ship-building, power plant, petrochemical

and machinery, etc.

There are single milling head and double

milling head; and the milling head can be standard facer or molding facer for

your options.

2. Main Parameters

|

Model

|

XBJ6

|

XBJ9

|

XBJ12

|

XBJ15

|

XBJ18

|

|

Suitable plate length m

|

6

|

9

|

12

|

15

|

18

|

|

Distance between hold-down and bed mm

|

80

|

|

Plate thickness mm

|

6—50

|

|

Milling angle °

|

0°—45° (can be altered)

|

|

Milling head model

|

TX32A or TX40A

|

|

Power and revolution of milling head

|

5.5kW, 1440rpm or 7.5kW, 1440rpm

|

|

Spindle revolution

|

125—630

|

|

Milling speed m/min

|

0.13—1

|

|

Fast forward and return speed m/min

|

3.5

|

|

Hydraulic pressure Mpa

|

≦3.5

|

|

Power supply

|

AC380V, 50HZ, 3P or tailor made

|

|

Above are our standard models and parameters, and it can be

designed and manufactured on request.

|

*We reserve the right to alter

specifications without prior notice.

3. Main features

The standard models of our fixed upper

press-beam edge milling machines have the following features:

The lower feeding speed is adjusted by inverter, meeting the

requirements of any speed milling and fast feedback. The upper milling unit has

function of motorized elevating, manual forwarding milling facer, manual

adjusting the milling head angle; the milling facer can adjusting any position for

the work piece milling, so that it can milling the straight side and 0-45°

beveling (adjusted by manual). The lower feeding speed is adjusted by inverter, meeting the

requirements of any speed milling and fast feedback. The upper milling unit has

function of motorized elevating, manual forwarding milling facer, manual

adjusting the milling head angle; the milling facer can adjusting any position for

the work piece milling, so that it can milling the straight side and 0-45°

beveling (adjusted by manual).

The principal axis is with great rigidity, great milling

characteristics. The gear is quenched and milled treatment, with high

precision, low transmission noise, whose speed is adjusted by joystick. The principal axis is with great rigidity, great milling

characteristics. The gear is quenched and milled treatment, with high

precision, low transmission noise, whose speed is adjusted by joystick.

Rail section is fixed on the lather; Rail is planed into shape with

quality mild steel, and then ground finely and surface quenched which ensuring

rail precision and abrasion-proof performance. Rail section is fixed on the lather; Rail is planed into shape with

quality mild steel, and then ground finely and surface quenched which ensuring

rail precision and abrasion-proof performance.

In order to positioning the work piece correctly, the lather rail

side has the stop rack unit, which can be pulled out manual and retracted into

the lather body after the work piece clamping. In order to positioning the work piece correctly, the lather rail

side has the stop rack unit, which can be pulled out manual and retracted into

the lather body after the work piece clamping.

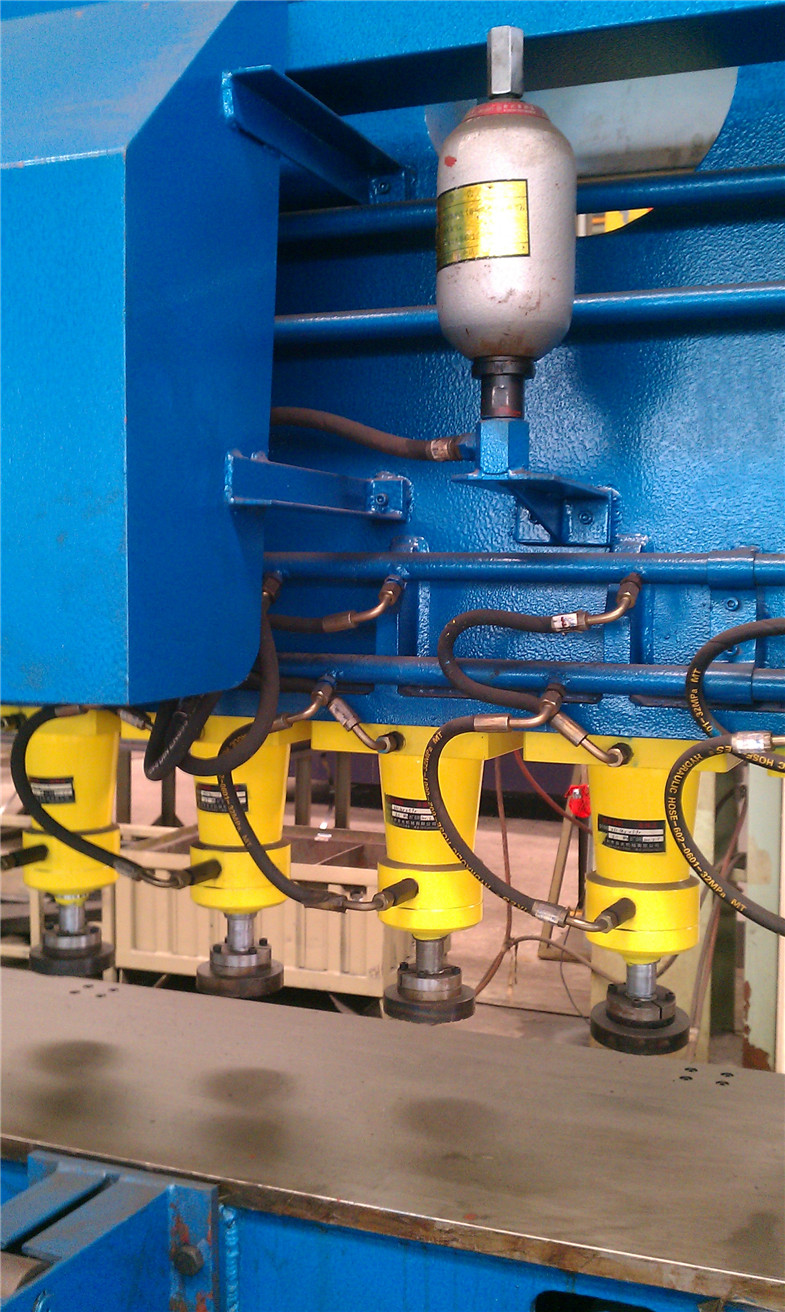

It has the automatic hydraulic press jack and manual screw jack at

the down position and press the work piece reliable, which can avoid the

milling shaking and decrease the noise. It has the automatic hydraulic press jack and manual screw jack at

the down position and press the work piece reliable, which can avoid the

milling shaking and decrease the noise.

There’s one set of work piece feeding rack at feeding side of

machine. There’s one set of work piece feeding rack at feeding side of

machine.

The up and down rail adopt 2-stage protection, the upper rail has

whole rail protect cover. The up and down rail adopt 2-stage protection, the upper rail has

whole rail protect cover.

Robust all steel fabrication with stable structure and good

rigidity, and no deformation after long time using; Robust all steel fabrication with stable structure and good

rigidity, and no deformation after long time using;

Standard facer available in any local market; Standard facer available in any local market;

Heat treatment to main welding parts

after welding; sand blasting treatment to main welding parts before painting; Heat treatment to main welding parts

after welding; sand blasting treatment to main welding parts before painting;

All motion parts have lubrication system; All motion parts have lubrication system;

Main electric elements are ABB/Siemens brands; Main electric elements are ABB/Siemens brands;

Standard color: Standard color:

Option features:

Movable upper press-beam edge milling machine; Movable upper press-beam edge milling machine;

Taiwan E-long 7.5KW milling head available; Taiwan E-long 7.5KW milling head available;

Double milling head available with milling angle -45°—0° and 0°—45°; Double milling head available with milling angle -45°—0° and 0°—45°;

4.

Reference photo

|